01

NANJING SPAREProducts Infomation

Download

| Chemical media | Max. Temperature Resistance (Degree Celsius) | |||

| Concentration % | Vinyl | m-Benzene | o-Phenylene | |

| Hydrochloric acid | 30 | 82 | 65 | Not recommended |

| Nitric acid | 35 | 38 | Not recommended | Not recommended |

| Sulfuric acid | 25 | 82 | 65 | Not recommended |

| Hydrofluoric acid | 10 | twenty four | Not recommended | Not recommended |

| Lactic acid | 100 | 82 | 65 | 60 |

| Hypochlorite | Saturated | 60 | Not recommended | Not recommended |

| Trisodium phosphate | 50 | 82 | Not recommended | Not recommended |

| Citric acid | All | 49 | Not recommended | Not recommended |

| Potassium hydroxide | 10 | 49 | Not recommended | Not recommended |

| Sodium hydroxide | 10 | 82 | Not recommended | Not recommended |

| Calcium hydroxide | 25 | 82 | 65 | Not recommended |

| Calcium hypochlorite | 25 | 82 | 65 | Not recommended |

| Ferric chloride | 100 | 82 | 65 | 60 |

| Aluminum chloride | All | 82 | 65 | 60 |

| Mercury chloride | 100 | 82 | 65 | 60 |

| Silver nitrate | 100 | 82 | 65 | 60 |

| Fuel | All | 38 | 38 | 38 |

| Ammonium salts | All | twenty four | Not recommended | Not recommended |

| Copper oxide | Glycerin | 52 | 52 | Not recommended |

| Sodium salt | All | twenty four | Not recommended | Not recommended |

| Zinc chloride | All | twenty four | twenty four | Not recommended |

| Acetone | 100 | 124 | Not recommended | Not recommended |

| chloroform | 100 | Not recommended | Not recommended | Not recommended |

| Copper salt | All | 82 | 65 | 60 |

| Phenols | 10 | twenty four | Not recommended | Not recommended |

| Ozone for water treatment | All | 38 | 38 | 38 |

| Bleaching solution (for paper mills) | All | 82 | Not recommended | Not recommended |

| Ammonia hydroxide | 30 | twenty four | Not recommended | Not recommended |

| Paper mill black liquor | All | 82 | Not recommended | Not recommended |

| All | 100 | 82 | 65 | 60 |

| Sulfur Dioxide | Saturated | 82 | 65 | 60 |

| Water | 100 | 82 | 65 | 60 |

| Alum | All | 82 | 65 | 60 |

| Chlorine water | Saturated | 49 | Not recommended | Not recommended |

NANJING SPAREProgressing

Fibres Roving+Fibre Guides

● Fiber reinforcements are precisely set-up and connected to mechanical pulling equipment.

Resin Bath

● Polymer resin in liquid form is pumped into a bath staged after the fiber reinforcement set-up.

● Process begins with reinforcing fibers being mechanically pulled through the resin bath where fibers are thoroughly saturated and impregnated with polymer resin.

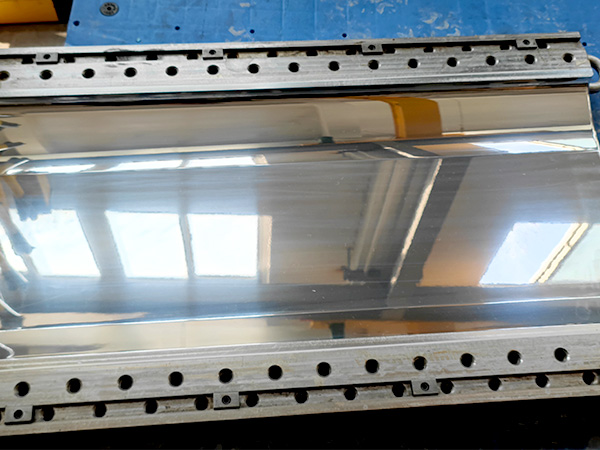

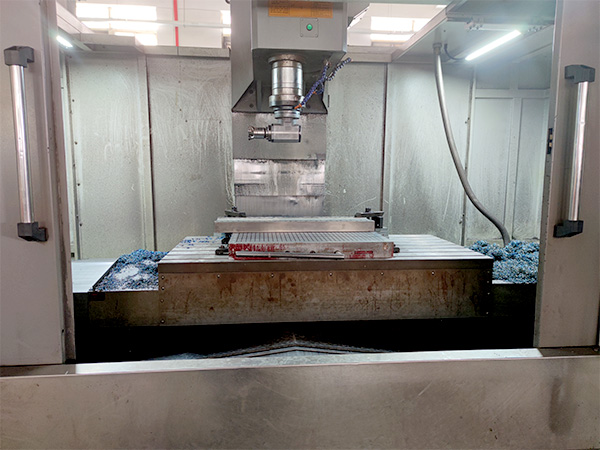

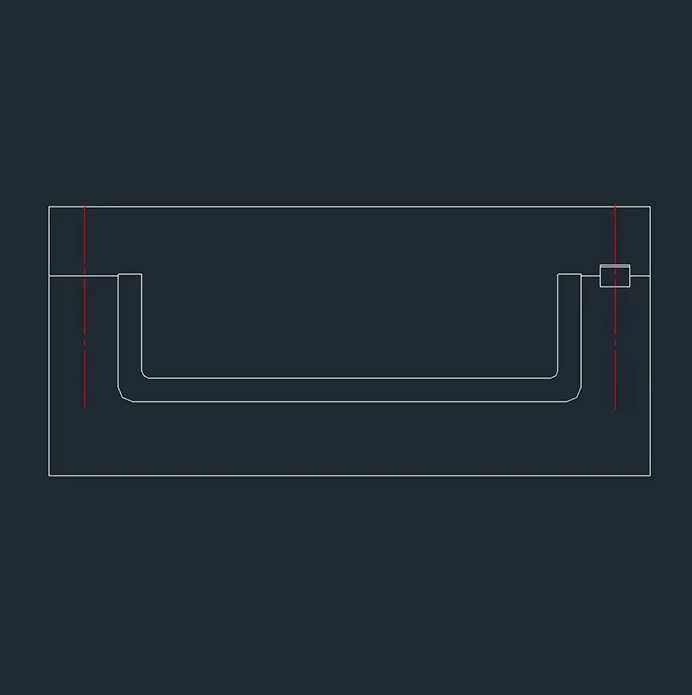

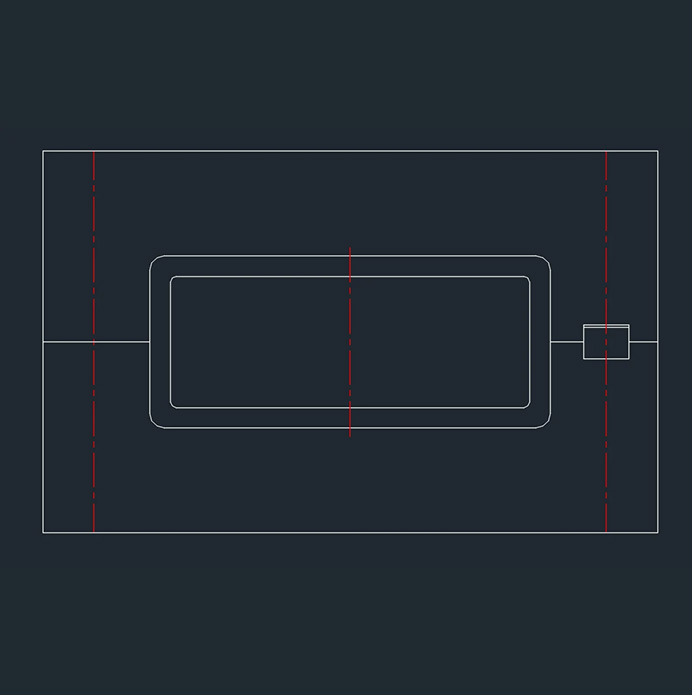

Heating Die

● The saturated fibers are then pulled through a machined-precision die with entry portal and internal cavity in the shape of the final product. The composite is formed and cured within the heated, steel die.

Pullers

● Upon exiting the die, the thermoset composite is cut to the desired length and is a finished part.

| Bonding | Tape connection or glue connection |

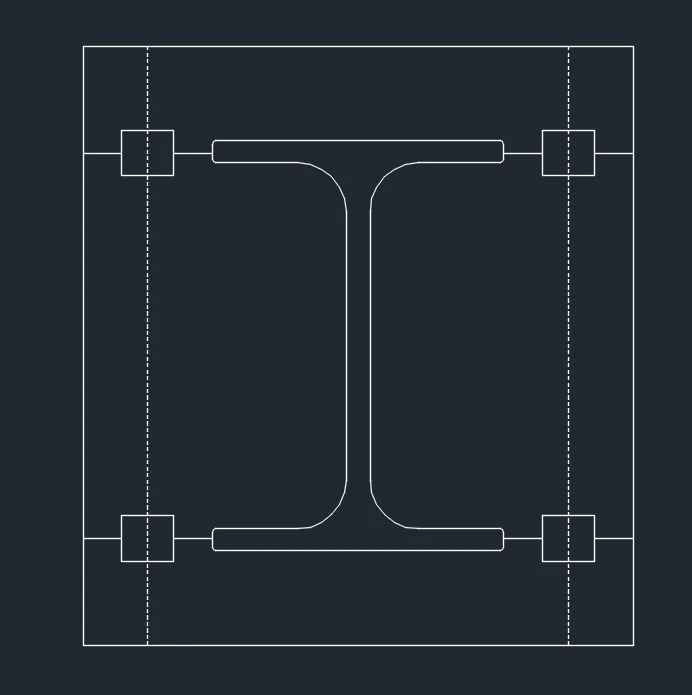

| Connection method | Bolting |

| Riveting | |

| Fasteners |