- FRP Cable Tray System

- FRP Connectors

- FRP Handrails And Fences

- FRP Moulding

- FRP Pultruded Grating

- Residence Building

- Tool Handle

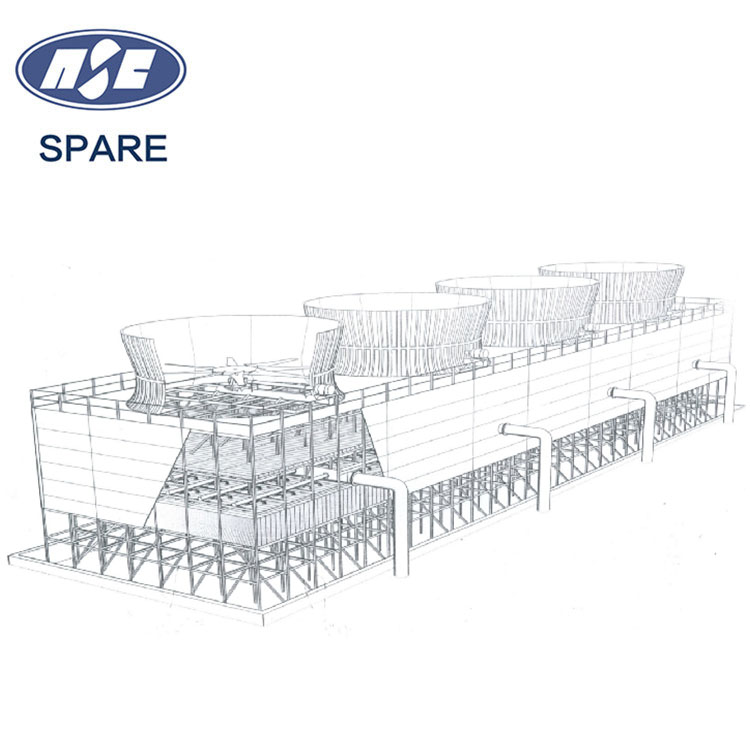

- Cooling Tower Structure

- FRP custom products

- Bridge Structure components

- FRP photovoltaic support

- Structural Component Applications

- Decking and Planting

- Decking and Planking

- FRP Assemblies

- FRP Decking and Planking

- FRP Building reinforcements

- FRP Structure shapes

01

Light weight and high strength FRP frame structure

Tower Structure The frame structure of the all-glass fiber reinforced plastic cooling tower adopts a uniform grid column structure type, and all columns, connecting diagonal braces and supporting beams are made of machine-made glass fiber reinforced plastic extruded profiles.

The support columns and diagonal braces are made of square fiberglass extruded square tubes, the axial and longitudinal support beams are made of fiberglass profiles, and the cooling tower frame structure is strengthened by diagonal braces to evenly transmit operating loads including wind loads and earthquake loads. onto a concrete foundation.

The end wall panels of the cooling tower, the enclosure panels above the air inlets and the partition panels inside the tower are all made of glass fiber reinforced plastic plates. The tower top platform uses a mechanical extruded anti-slip deck. The tower top and the tower maintenance walkway railings are made of glass fiber reinforced plastic square tubes. The stairs to the tower The frame structure and pedals are made of machine-made fiberglass pultruded profiles.

All frame connections and splicing of the all-glass fiber reinforced plastic cooling tower are made of stainless steel bolts without any adhesive joints.

Blade: Cooling tower blade produced by pultrusion process. Blade is an important part of cooling tower fan. Currently, common fan blades mainly include fan blade seat assembly and fan blade assembly. When the fan blade is assembled, it is assembled by bolts and nuts. Connect and fix the fan blade seat assembly and fan blade assembly.

The frame structure of the all-glass fiber reinforced plastic cooling tower adopts a uniform grid column structure type, and all columns, connecting diagonal braces and supporting beams are made of machine-made glass fiber reinforced plastic extruded profiles.

The end wall panels of the cooling tower, the enclosure panels above the air inlets and the partition panels inside the tower are all made of glass fiber reinforced plastic plates. The tower top platform uses a mechanical extruded anti-slip deck. The tower top and the tower maintenance walkway railings are made of glass fiber reinforced plastic square tubes. The stairs to the tower The frame structure and pedals are made of machine-made fiberglass pultruded profiles.

All frame connections and splicing of the all-glass fiber reinforced plastic cooling tower are made of stainless steel bolts without any adhesive joints.

Blade: Cooling tower blade produced by pultrusion process. Blade is an important part of cooling tower fan. Currently, common fan blades mainly include fan blade seat assembly and fan blade assembly. When the fan blade is assembled, it is assembled by bolts and nuts. Connect and fix the fan blade seat assembly and fan blade assembly.

Product Drawing