| Angle | Series Number | A | B | t | NO. |

| 1 | 170 | 80 | 5 | L-0330 |

| 2 | 152.4 | 152.4 | 9.52 | L-0803 | |

| 3 | 150 | 80 | 3 | L-0641 | |

| 4 | 101.6 | 101.6 | 6.35 | L-0637 | |

| 5 | 100 | 100 | 8 | L-0035 | |

| 6 | 100 | 100 | 6 | L-0562 | |

| 8 | 100 | 50 | 8 | L-0019 | |

| 9 | 90 | 60 | 5 | L-0028 | |

| 10 | 88.9 | 88.9 | 6.35 | L-0653 | |

| 11 | 76.2 | 76.2 | 6.35 | L-0022 | |

| 12 | 76 | 76 | 9.5 | L-0023 | |

| 13 | 75 | 75 | 10 | L-0030 | |

| 14 | 75 | 75 | 6 | L-0027 | |

| 15 | 70 | 30 | 6.35 | L-0038 | |

| 16 | 61.8 | 31.7 | 2.5 | L-0343 | |

| 17 | 60.5 | 43.8 | 2.8 | L-0461 | |

| 18 | 60 | 40 | 7 | L-0701 | |

| 19 | 60 | 60 | 8 | L-0034 | |

| 20 | 50.8 | 50.8 | 6.35 | L-0026 | |

| twenty one | 50 | 50 | 3 | L-0033 | |

| twenty two | 50 | 50 | 4 | L-0037 | |

| twenty three | 50 | 35 | 5 | L-0032 | |

| twenty four | 50 | 50 | 5 | L-0029 | |

| 25 | 50 | 50 | 6 | L-0464 | |

| 26 | 50 | 48 | 3 | L-0805 | |

| 27 | 50 | 38 | 3 | L-0773 | |

| 28 | 45 | 45 | 5 | L-0021 | |

| 29 | 40 | 40 | 4.2 | L-0025 | |

| 30 | 38.1 | 38.1 | 6.35 | L-0652 | |

| 31 | 35 | 35 | 5 | L-0020 | |

| 32 | 28 | 28 | 3 | L-0036 | |

| 33 | 25 | 25 | 3 | L-0031 | |

| 34 | 50 | 50 | 2.8 | L-0438 | |

| 35 | 60 | 40 | 2.8 | L-0421 | |

| 36 | 120 | 60 | 2.8 | L-0427 | |

| 37 | 100 | 25 | 2.8 | L-0408 | |

| 38 | 120 | 100 | 5 | L-0514 | |

| 39 | 70.5 | 13.2 | 3.3 | L-0610 | |

| 40 | 69.5 | 15 | 5 | TL-0611 | |

| 41 | 30 | 36 | 3 | L-0818 |

- FRP Cable Tray System

- FRP Connectors

- FRP Handrails And Fences

- FRP Moulding

- FRP Pultruded Grating

- Residence Building

- Tool Handle

- Cooling Tower Structure

- FRP custom products

- Bridge Structure components

- FRP photovoltaic support

- Structural Component Applications

- Decking and Planting

- Decking and Planking

- FRP Assemblies

- FRP Decking and Planking

- FRP Building reinforcements

- FRP Structure shapes

01

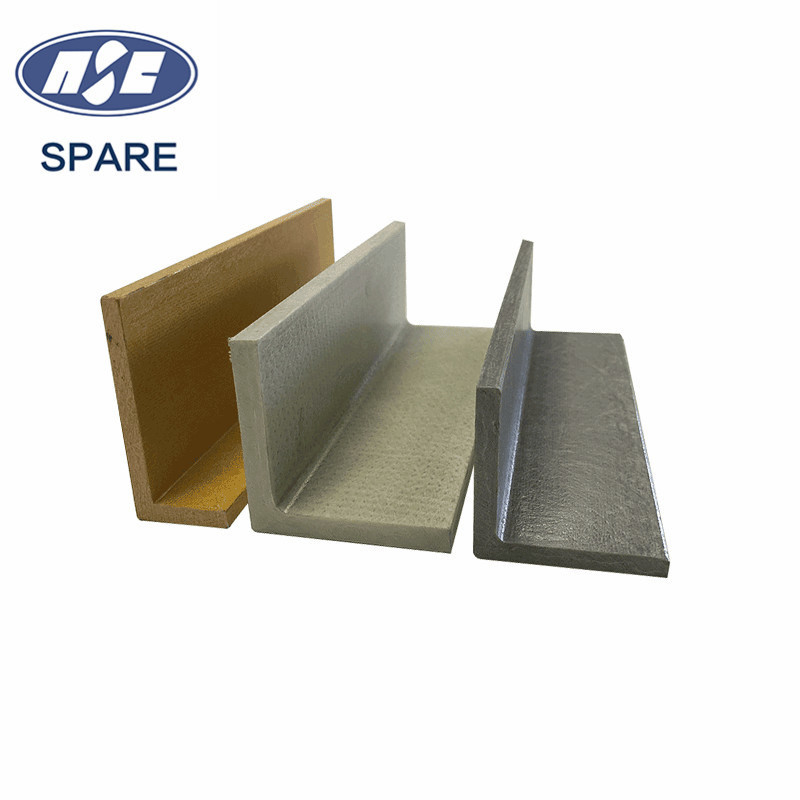

Lightweight and high strength FRP angle

Product Parameter

Product Drawing

Product ApplicationFRP angle steel can be composed of various stress-bearing components according to the needs of different structures, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, ships, industrial furnaces, reaction towers, container racks, cable trench supports, power piping, busbar support installation and warehouse shelves, etc.

FRP angle steel can be composed of various stress-bearing components according to the needs of different structures, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, ships, industrial furnaces, reaction towers, container racks, cable trench supports, power piping, busbar support installation and warehouse shelves, etc.

Benefits of Pultruded Fiberglass Angles ● Pultruded fiberglass angles have many advantages and are more durable and versatile than traditional materials such as wood, steel or aluminum. ● The pultrusion process produces stronger components with exceptional tensile strength, dimensional stability and rigidity. It can also create custom shapes and profiles of virtually any size. ● Pultruded fiberglass angles are lightweight – they can be 30% lighter than aluminum and 70% lighter than steel without sacrificing any strength. In addition, they are consistent in strength and do not deform easily upon impact. ● They can be easily machined, butted, slotted, chamfered, rounded and pointed with simple tools. Work with FRP products requires less heavy equipment and is, therefore, usually safer and less costly. ● Pultruded FRP angles do not conduct heat or electricity, so it is ideal as a protective barrier between hot or electrically charged parts and the end user. In addition, the non-magnetic electromagnetic transparency of this material makes it suitable for many special applications. ● FRP is highly durable, chemically resistant and corrosion resistant. Pultruded fiberglass corners will not rot or degrade from prolonged exposure to moisture, extreme temperatures or UV radiation. ● Pultruded fiberglass angles have an extremely long lifecycle (over 15 years) with very low maintenance cost and requirements compared to organic materials (e.g., wood) or rust-prone ones (e.g., iron or steel.) ● FRP products offer the versatility required by today's manufacturing industry to create highly-customized or intricate components that meet a variety of design needs.

● Pultruded fiberglass angles have many advantages and are more durable and versatile than traditional materials such as wood, steel or aluminum.

● The pultrusion process produces stronger components with exceptional tensile strength, dimensional stability and rigidity. It can also create custom shapes and profiles of virtually any size.

● Pultruded fiberglass angles are lightweight – they can be 30% lighter than aluminum and 70% lighter than steel without sacrificing any strength. In addition, they are consistent in strength and do not deform easily upon impact.

● They can be easily machined, butted, slotted, chamfered, rounded and pointed with simple tools. Work with FRP products requires less heavy equipment and is, therefore, usually safer and less costly.

● Pultruded FRP angles do not conduct heat or electricity, so it is ideal as a protective barrier between hot or electrically charged parts and the end user. In addition, the non-magnetic electromagnetic transparency of this material makes it suitable for many special applications.

● FRP is highly durable, chemically resistant and corrosion resistant. Pultruded fiberglass corners will not rot or degrade from prolonged exposure to moisture, extreme temperatures or UV radiation.

● Pultruded fiberglass angles have an extremely long lifecycle (over 15 years) with very low maintenance cost and requirements compared to organic materials (e.g., wood) or rust-prone ones (e.g., iron or steel.)

● FRP products offer the versatility required by today's manufacturing industry to create highly-customized or intricate components that meet a variety of design needs.